- Home

- Static VAR compensator (SVC)

- SVC for Industries

SVC for Industries

Static Var Compensator / Static Var Compensation

Meishan Iron & Steel Corporation is a well-known steel manufacturer within China’s largest steel group Baosteel. Meishan Steel has a total production capability of around three million tons of steel every year.

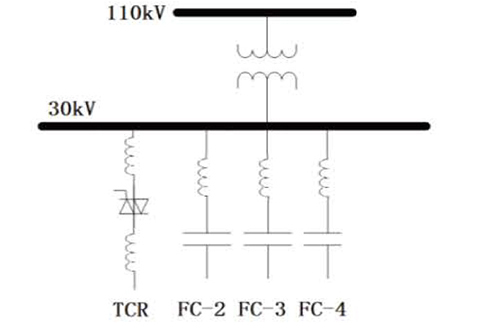

In 2001 Meishan steel installed a SVC for its ladle furnace, rated at 30kV/20Mvar, to handle the power quality problems caused by the furnace such as power factor, harmonics, three-phase imbalance, voltage fluctuations and flicker.

The SVC was operating normally after it was commissioned in the year 2001. However in the year 2008, the thyristor valve suddenly broke down during a SVC fault. The customer contacted the original supplier many times but they could not come up with any proper solution at an agreeable cost. Considering of the high cost and slow response during after sales services, Meishan steel finally came to RXPE seeking support.

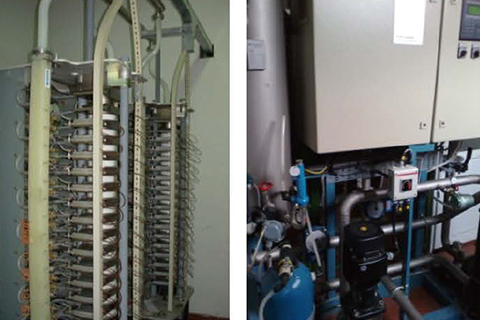

It was found the SVC was originally designed as a TCR+FC type with ETT thyristors and water/water cooling method. After a site inspection by RXPE engineers, it had been confirmed the yard equipment including those reactors, capacitors, switchgears etc. as well as the water cooling system can be reused with some minor maintenance. The thyristor valve and the control and protection system need to be replaced. Besides, the interface program to the cooling control panel had also been modified to get adapted to the original water cooling system.

The upgraded project was successfully completed in 2008. After upgrading the SVC and getting it back into normal operation again successfully, RXPE valves and the control and protection system have been running well ever since.

All the power quality performances are eligible according to the site acceptance test after upgrading. What's more, Meishan was also happy to have found an economical solution for their after sales services and spare parts.

After one year of stable operation of this upgraded SVC, Meishan steel performed the same upgrade to the other SVC in their factory, a 10kV/45Mvar SVC for rolling mill that was originally commissioned in 1993 with even older thyristor valves and control system. Both SVCs have been operating normally after upgrade.

we are engaged in the design and manufacturing of power compensation equipment and high-power power electronic equipment. Our full line of products can meet the needs of numerous applications from power generation, transmission, and distribution to terminal loads, providing solutions for customers in terms of improving power quality, optimizing control and increasing energy efficiency. We supply power quality solutions (SVC, SVG, SC) to customers all around the world.